HDCNG® Commercial Framework, Project Management and Execution

M.E.S. have brought together a team of skilled professionals from the resources sector with significant experience in executing complex projects.

We have a robust and disciplined project management and execution framework that has been developed in association with our pathfinder customers and is tailored to specific site requirements.

Commercial Framework

M.E.S. works closely with the mine owner/operator, under NDA, to quantify the commercial opportunity as follows:

- Number, brands and models of machines in operation

- Assess fleet dual fuel conversion requirements

- Location of operational sites and existing infrastructure plan

- Preferred order of implementation (if multiple sites)

- Type and extent of HDCNG® infrastructure required

- Availability of commercial quantities of locally sourced gas feedstock

- Customer sponsored site visit to gather:

- Fleet operational data

- Work patterns

- Site operational data including current/future fleet duty & maintenance cycles and existing refuelling practices

- Specific safety management and operational plans

- Operational considerations impacting on conversion timelines

- Key commercial terms agreed

Project Implementation

Once a commercial framework is in place between M.E.S. and the mine owner or operator, detailed design is carried out, economic fundamentals are reconfirmed and FID is agreed.

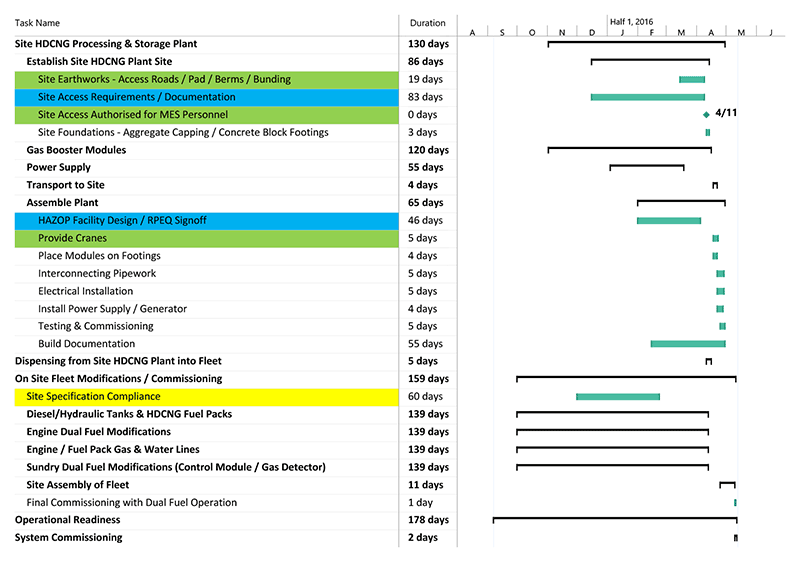

A detailed Project Execution Plan with agreed timelines and milestones is developed in conjunction with the site. Fleet conversion, facilities construction and commissioning is carried out.

Typical elements covered by the execution plan are:

- Regulatory framework

- Component ordering

- Fleet conversion plan

- Gas collection, production facility design and construct

- Virtual pipeline, site and on-truck storage

- Mine truck refuelling method assessment and design (automated, semi-automated or manual)

- Documentation – meeting mine owner/SSE/EEM, regulatory and M.E.S. requirements

- Gas ops

- Mine ops interface

- Safety management plans