M.E.S.’ haul truck fuel packs utilise HDCNG® proprietary gas cylinder filling technology to achieve energy densities approximately double that of conventional CNG storage systems, and approaching two thirds of the density of LNG without the operational complexity and cost of LNG cryogenic storage and handling. This enables mine trucks to achieve high levels of diesel displacement whilst carrying sufficient fuel on board for a full work shift and not adversely affecting payload.

Key elements of truck chassis conversion:

- Customised wiring looms to accommodate the dual fuel system;

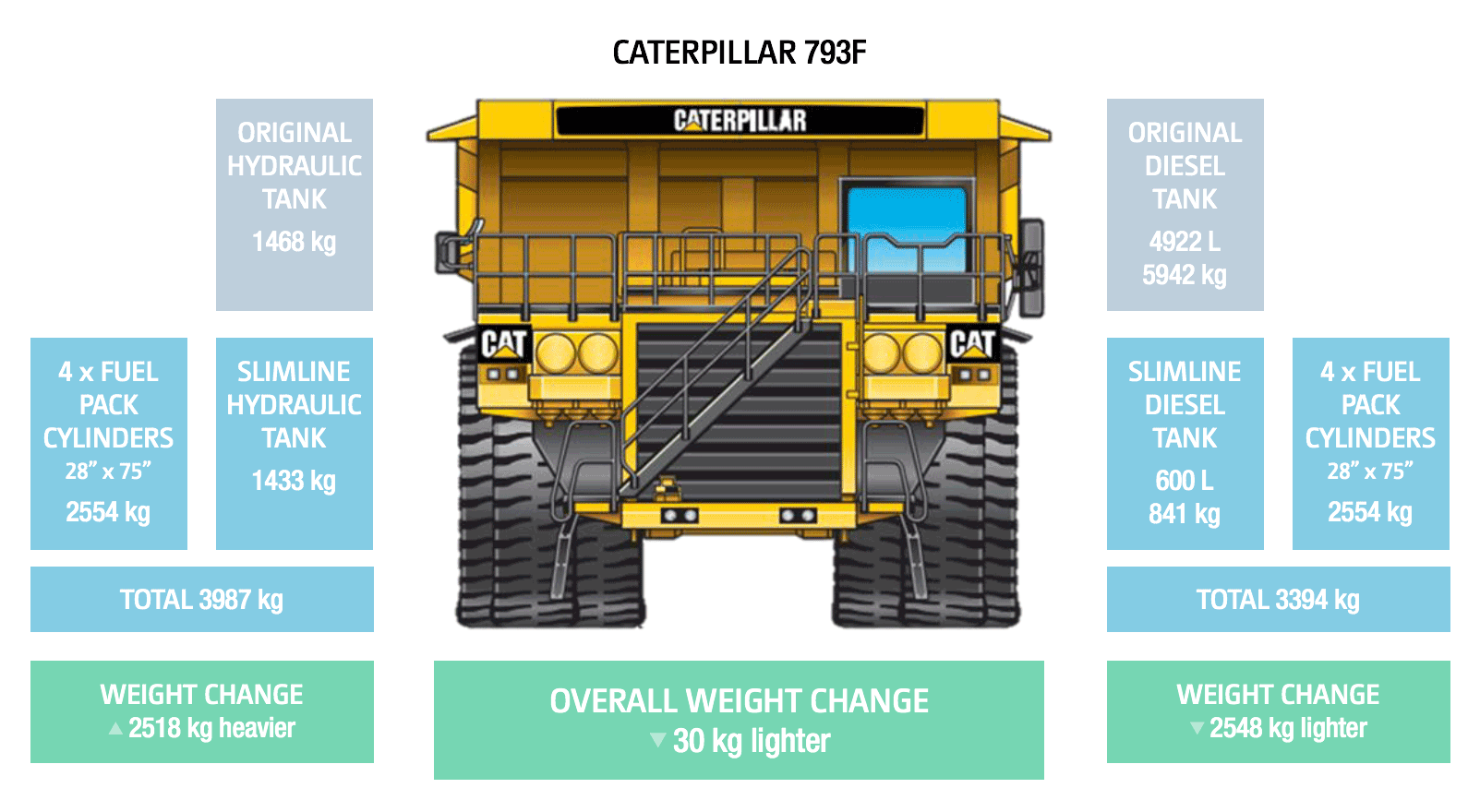

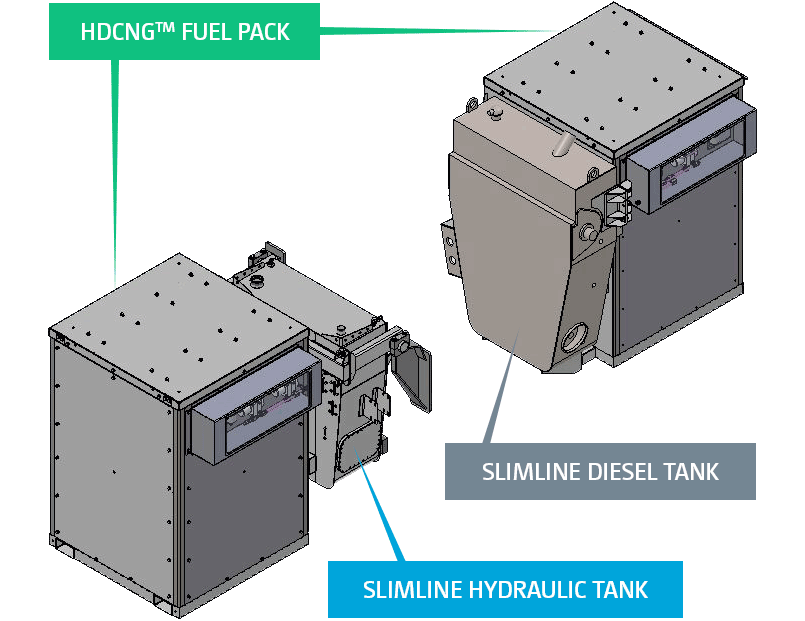

- Replacement of the existing fuel storage tank with a new “slimline” diesel tank;

- Replacement of the existing hydraulic tank with a new “slimline” hydraulic tank should this be required;

- Installation of M.E.S.’ haul truck HDCNG® Fuel Packs on both the driver’s side and offside of the truck adjacent to the diesel and hydraulic tanks;

- All accompanying dual fuel distribution lines and connection to engine bay;

- All associated and fully compliant gas/engine safety control systems.

HDCNG® Fuel System

M.E.S.’ HDCNG® mine truck dual fuel technology has been developed to achieve sufficient fuel storage quantities on board the machine for a full work shift of up to 12 hours. In mine haul trucks, a slimline diesel fuel tank (and if required a slimline hydraulic oil tank) replaces the existing tanks allowing for the introduction of HDCNG® Fuel Packs for the storage of gas on the machine.

Compliance

All conversion work is undertaken in a designated work area within the mine site. The work area will be fully compliant and registered as required by the relevant jurisdiction. M.E.S. will ensure that the work complies with all relevant safety requirements with relevant certifications of conformity issued.

Engine Conversion

Dual fuel engine conversions have a long history, often marred by reduced engine power and engine failures. M.E.S.’ approach to dual fuel engine conversion differs significantly from past configurations with precise fuel mixing on individual cylinders, advanced detonation algorithms, and unique control architecture that does not interfere with the underlying operation of the complex truck control systems.This last feature allows OEM ECU updates that are transparent to the M.E.S. control system ensuring 100% forward compatibility.

Dual fuel engine conversions have a long history, often marred by reduced engine power and engine failures. M.E.S.’ approach to dual fuel engine conversion differs significantly from past configurations with precise fuel mixing on individual cylinders, advanced detonation algorithms, and unique control architecture that does not interfere with the underlying operation of the complex truck control systems.This last feature allows OEM ECU updates that are transparent to the M.E.S. control system ensuring 100% forward compatibility.

The conversion process is relatively simple, non-invasive and is designed to complement and not replace existing systems in these technically advanced engines.

Key elements of M.E.S.’ non-invasive dual-fuel engine technology:

- OEM Diesel Injection hardware untouched

- No software changes required to the OEM engine controllers.

- OEM updates can be continually applied to the engine.

- Electronic system control architecture is designed agnostic of OEM systems.

- Custom electronic hardware and software developed and implemented to take individual diesel cylinder fuel injector requests and map this to requested fuel flow.

- System takes direct control of the diesel injector enabling variation of timing and also additional multi-fire as required.

- System uses multiple commercially available precision CNG injectors to create an accurate per cylinder, narrow injection width, gas injection system.

- System has adaptive knock control/monitoring with one acoustic sensor per two cylinders.

- System monitors exhaust port temperature to establish trim levels for diesel injector turn down.

- Fuel rail systems are non-invasive and no OEM castings are modified. Injection is via custom injector plates inserted between the inlet manifold and head.