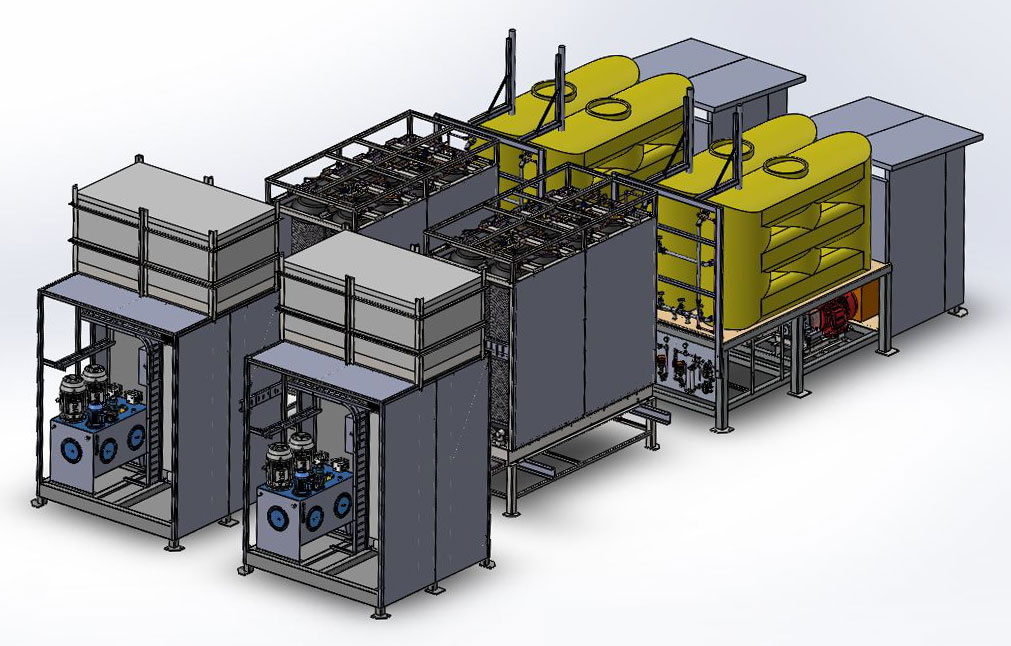

Gas Processing and HDCNG® Production Facility

The gas compression hub comprises drying, compression, and the HDCNG® fuel pack/storage module filling facilities which incorporate chilling and transfer systems. Gas is compressed from delivery pipeline pressure typically using reciprocating compressors and is then further compressed with hydraulically powered gas boosters.

The gas is then chilled and directed into the High Density Compressed Natural Gas dual fuel packs that are used either for installation on mine trucks for insitu fast fill refilling or as “swap and go” cassettes. In cases where HDCNG® is transported to the user location, specially designed transport crates are used.

- Multiple gas compressor modules installed adjacent to the gas supply point. Each module contains:

- Gas compressor

- Engine-driven 3 phase electric motor

- Radiator package

- Interstage and heat exchangers

- Post compressor heat exchanger

- Gas Booster modules installed to supply gas into the HDCNG® Cassettes or cylinders. Each module contains:

- Gas boosters which will operate at high pressure

- Heat exchangers

- Hydraulic power pack

- Chillers

While the area required for a typical gas processing & HDCNG® production facility is quite small, when allowing for the turning circle of transport vehicles approximately 1 hectare of land area is required.